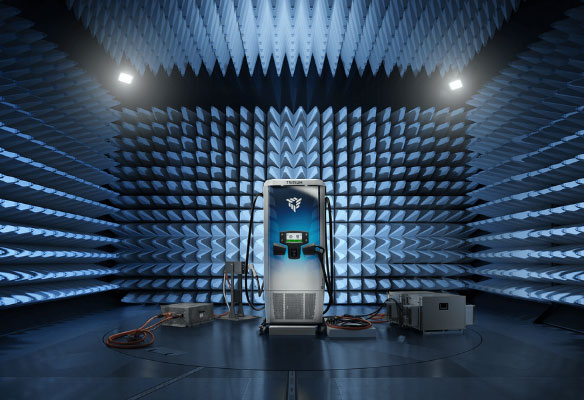

Tritium EV Charger Testing Facility

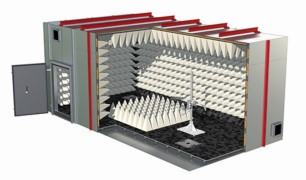

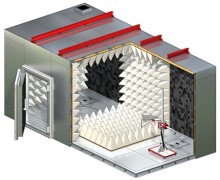

In 2021, Tritium opened a world-class compliance testing facility at the company’s Brisbane headquarters. This new facility is capable of accelerating testing, prototyping, compliance and certification, allowing products to be bought to market in shorter timeframes & with greater cost efficiency. It features an EMC chamber with one of the highest power test capabilities in the world. Built and delivered by Fuseco & Frankonia, construction was completed in 5 months.

.jpg)