VSD's & Harmonics

VSD's & Harmonics

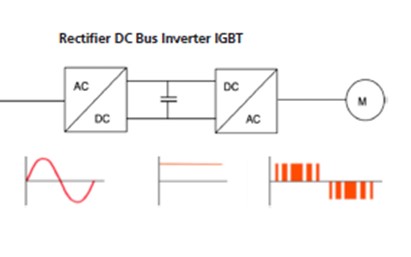

For motors to be used in a practical and useful way, we need to be able to control their speed of operation. A Variable Speed Drive (VSD), also known as a Variable Frequency Drive (VFD) is a programmable device that controls motor speed. A VSD works by having a rectifier section at the input and this creates DC voltage on the DC bus (needed for switching). The inverter section at the output side provides the Pulse Width Modulation (PWM) waveform. A drive changes the speed of the motor by changing the frequency to the motor.

As an aside, the impedance of the motor is determined by the inductive reactance in the windings, and it changes as the frequency changes. PWM is employed to control the voltage and frequency to the motor drive. DC voltage is applied to the motor by controlled pulses at high frequency, which results in voltage that approximates a sine wave of the chosen frequency. This PWM method creates harmonics in the system. The switching also creates radio frequency interference (RFI) and voltage spikes that can be up to 1200V at the motor terminals.

The high switching frequency can also lead to ‘capacitive bearing currents’ that flow through the motor bearings and can damage the bearing surfaces. A portion of the harmonics are reflected back to the VSD by the motor, creating further issues in the electrical environment.

The presence of harmonics in an electrical system can result in:

- Degradation of motors, especially the bearings and insulation = higher costs.

- Significant reduction of the lifespan of equipment due to excessive heat = higher costs.

- Although you will get billed for the power that you are supplied, a large percentage of that power may be unusable = higher costs.

- Unusual events such as flickering lights, alarms going off, or MCB’s, MCCB’s, RCD’s and Earth Leakage devices tripping for no apparent reason = more down time = higher costs.

Sellers of VSDs please note:

- Customers are becoming more aware of the damage caused by VSD related harmonics. Harmonic mitigation products are now being offered to customers as a ‘value-add’, in essence as an ‘insurance policy’ against the detrimental effects of harmonically rich environments, enhancing the longevity of both the motors and the drives.

- These products are also used on the input side of a drive in situations where harmonics are causing issues and in cases where a site needs to comply to supply authority requirements for harmonic content coming back onto the grid.

- Harmonic mitigation products MUST be considered for applications with long cable runs and/or multiple VSDs in the one environment.

From the moment the AHF and SVG units were turned on our power factor issues were a thing of the past. At both sites our PF is now 0.99 on all phases all the time, the units react instantaneously to our fluctuating load and power factor and the result has been an excellent return on investment.

Brad Kilner

OPERATIONS MANAGER AT KILNER'S ENGINEERING

Top FAQs

For electrical systems to function in their intended manner without significant loss of performance or life, they require a supply of electricity that is of good quality. Good quality electrical power has the following characteristics:

- It must have a continuity of service (not be interrupted).

- It must have a very low Harmonic content.

- It must have a very low variation in the voltage magnitude.

- It must have very low transient voltages and currents.

The term 'clean power' is used to describe electricity that is considered to be of good quality (see above) with particular reference to a very low harmonic content. Therefore, the term 'dirty power' is used to describe electricity that is considered to be of low quality (opposite to the above) with particular reference to a very high harmonic content.

In Australia, our electricity is supplied in alternating current at a frequency of 50Hz. In alternating current (AC) the movement of electric charge periodically reverses direction. In direct current (DC), the flow of electric charge is only in one direction. 50Hz means that the AC has a frequency of 50 cycles per second. This is also known as the 'fundamental' frequency. AC is the form in which electricity is delivered to businesses and residences. Most electrical devices (such as motors) need clean electricity to function properly. This means that the electrical supply needs to be a clear sinusoidal wave.

In simple terms, harmonics are extra frequencies that when present in an electrical circuit, distort the AC sine wave. A harmonic of a wave is a component frequency of the signal that is an integer multiple of the fundamental frequency. For example, if the fundamental frequency is f, the harmonics have frequencies 2f, 3f, 4f... etc.

Harmonic frequencies are equally spaced by the width of the fundamental frequency and can be found by repeatedly adding that frequency. In the case of the Australian electricity supply, the fundamental frequency is 50Hz. The frequencies of the harmonics are 100Hz, 150Hz, 200Hz, 250Hz, 300Hz, 350Hz and so on.

If you occasionally experience some unexplained occurrences such as flickering lights, alarms going off, or MCB's, MCCB's, RCD's and Earth Leakage devices tripping for no apparent reason, you are most likely experiencing harmonics in your electrical environment. Other signs are cables running hot, hot switchboards or overheating motors. If you are replacing your motor's bearings & insulation often, that's a strong indication of the presence of harmonics.

Learn more

Harmonics are very harmful within an electrical system and can have serious consequences. For example, the presence of harmonics reduces the life of equipment. It is possible that the investment that you made in your motors & drives will not be realised if they are damaged and need replacing before their expected life span. This can be very expensive. Harmonics cause things to run hot, which cause stress on the cables and equipment.

In the long term, this degrades an electrical system. The presence of harmonics will also mean that although you will get billed for the power that you are supplied, a large percentage of that power may be unusable. Harmonic mitigation is taking action to minimise the presence of harmonics in your electrical system and can achieve great cost savings.

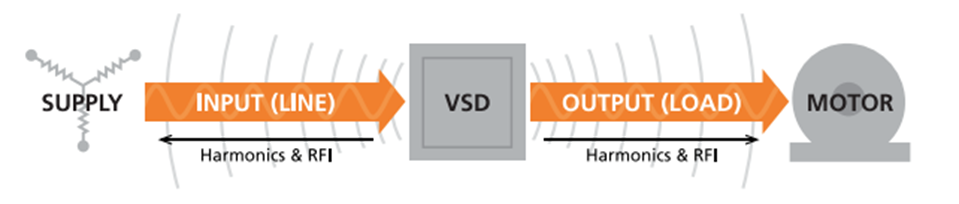

Variable Speed Drives (also known as Variable Frequency Drives) are prolific creators of harmonics in electrical systems and as a result, most of the harmonic mitigation effort focuses on the input side and output side of a VFD.

Power Quality products act as filters in electrical systems to limit harmonics and radio frequency interference (RFI). Essentially, they turn 'dirty' power into 'clean' power. Variable Speed Drives (VSD's) are prolific creators of harmonics in electrical systems and as a result, most of the harmonic mitigation effort focuses on the input side and output side of a VSD. Depending on the specific situation, there are a variety of products that are used to mitigate harmonics.

In addition, there are many ways to reduce the effects of RFI, depending on your application. For conducted RFI, you can choose from a large range of RFI filters, chokes & pulse transformers. RFI filters are available as feedthrough components, or as PCB filters, IEC inlet filters and power entry modules, 3-phase filters, 3-phase and neutral line filters, output filters, EMC/EMI chokes and pulse transformers. For radiated RFI, you can choose from a large range of shielding products.

Fuseco's Power Quality Consultants can assist by conducting a site analysis or simply providing advice based on the details of the particular electrical system.

Yes! This is the best way to eliminate harmonic related problems.

Harmonics mitigation is most cost-effective when 'designed in'. Mitigation in existing installations is possible but more than likely to cost significantly more without the performance of an 'ab initio' approach.

Good reasons for designing-in harmonics mitigation relate to economy, performance and reliability. All three of the following reasons have dollar implications.

- Economy: Harmonics cause energy to be wasted. Someone has to pay for this and supply authorities have reflected this in general tariffs. Expect this to end as increasing Federal and State political pressure to limit cross-subsidisation in electricity tariffs, forces supply authorities to penalise industrial and commercial consumers straining the 'poles and wires'.

- Performance: Harmonics degrade the performance of equipment sensitive to power quality causing productivity losses, expenditure in service, and additional capital expenditure in replacing life-span compromised equipment such as motors.

- Reliability: The electrical reticulation network inside a building or factory has to be 100% available. Interruption because of breakdowns including false tripping of protective gear has severe cost implications and loss of profits through production interruption.

Harmonic mitigation solutions should be tailored to the type of application. In many ways each installation is unique but broad guidelines apply.

Commerical premises

The three-phase loads are generally HVAC, moving walkways and escalators, and elevators. HVAC plant generates significant harmonics.

Single-phase loads usually provide the highest aggregate harmonic load. Primary sources are IT equipment, and lighting ballasts. Load balancing for single-phase circuits is an important design consideration when there is high harmonic content. Two-phase loads are less frequent but might be reserved for some commercial kitchens.

Changes in tenancies, and expansion of facilities (more offices, shops, etc) can overload the reticulation because of increases in harmonic content. The capacity of a sub-station transformer can easily be surpassed unless harmonic mitigation has been installed.

Industrial plants

Many loads are three-phase, three-wire. Sub-station transformers are likely for large consumers connected to medium voltage distribution and plant expansion can challenge the sub-station beyond capacity.

Single-phase loads in aggregate are likely to be less than three-phase loads. Careful consideration of circuit and load mitigation will provide high power quality (eg: mitigation of negative sequence harmonics, commutation notching from converters) and allow control gear (PLCs, micro-controllers, industrial bus systems) to operate from clean supply.

Power factor is often low or variable due to loading and unloading of motors. Consideration of power factor control in combination with harmonic mitigation is important and best done at the design phase.

Voltage distortion at the point of common coupling

Harmonics mitigation adds cost to electrical installations and for that reason is often ignored. Sometimes a ‘suck it and see’ policy is adopted.

Harmonics are not just an internal problem. They are exported into the supply system in spite of interposing transformers—even the ubiquitous third harmonic, since installations are never phase-balanced.

If the supply authority complains about the degree of voltage distortion at the point of common coupling (pcc) harmonic filtering might be specified. Note that the relevant standard for harmonic voltage distortion in Australia is AS/NZS 61000.3.6. Supply authorities can insist on their own maximum voltage distortion levels.

Demand increased by harmonics

As energy regulators look more closely at 'gold-plating' of poles and wires, often defended on the basis of having to cater for high demand intervals, consumers can expect considerable additional charges for poor power factor and/or high apparent power demand. Flattening demand peaks is the single most important way of achieving cost-effective distribution systems.

Demand is measured in various ways by:

- Maximum kilowatt-15/30 minute consumption

- Maximum kilovolt-amp-15/30 minute demand (apparent power)

- Maximum kilovolt-amp reactive (kVAr)-15/30 minute reactive power demand

There can also be combination of the above demand parameters and power factor, this normally being the displacement power factor. Harmonics severely lower power factor and therefore increase the apparent power.

Sub-station transformers affected by harmonics

Consumers who buy electrical energy at medium rather than low voltage will have a sub-station transformer which may or may not owned by them but the problems caused by harmonics will be owned by them. Harmonics can severely de-rate the transformer and it is not an exaggeration that in Australia not much attention has been paid to 'harmonics-hardened' transformers. Eddy current losses, proportional to the square of both the amplitude and harmonic frequency will shorten transformer life span.

Wiring losses and reliability

Proximity and skin effects in conductors due to harmonics will often increase energy losses well in excess of the I2R losses at the fundamental frequency (50 Hz). These additional losses can wreck switchboards, overload conductors including neutrals and cause voltage distortion in the customer’s installation. Reliability of protection is affected. Magnetically tripped breakers can be tripped through severe current distortion (very high peak current) and thermally tripped breakers through the heating effects of harmonic current components. Harmonics can therefore upset coordination of protective gear. Residual current devices (RCDs) can also malfunction.

Design rules

Energy waste in the reticulation system is best avoided by harmonics mitigation as close to the harmonics generating sources as possible. Economies can be achieved by aggregating some harmonics generating loads for example variable speed drives. Large rating loads are often best connected on separate circuits. Single-phase loads are generally most economically mitigated at sub-distribution board level using three-phase, 4-wire harmonic filters (active filters are recommended for high variability loads).

Neutral current compensation can be a problem in the case of unbalanced phases, and zero sequence (3rd, 9th, etc) harmonic compensation best achieved on a per phase basis. Transformer selection for sub-stations should be on the basis of having a line diagram of the installation with predicted harmonic content available. For installations with stand-by generators, mitigation filters should avoid creating leading power factors. For installations using passive capacitor-bank displacement power factor correction, detuning chokes have to be employed to avoid resonance problems.

As power utilities continue to be pushed to the limits of supply capability, rising energy costs and decreasing power quality will continue to be an issue for consumers. Users continually search for ways to not only reduce energy costs, but also ensure their processes will continue to operate, no matter the quality of the incoming power. To accomplish this, more and more variable frequency drives, UPS systems, and other non-linear loads are being installed. The usual waveform of an alternating current (AC) is generally that of a sine wave or a sinusoidal waveform. This is considered the fundamental waveform. Linear loads draw current in proportion to the sinusoidal voltage. Non-linear loads, such as drives, change their impedance by conducting current only near the peak of the wave. Switching loads on and off during the waveform results in non-sinusoidal current pulses. These pulses introduce reflective currents (harmonics) back into the power distribution system. The non-sinusoidal waveforms have the fundamental wave plus integral multiples of that fundamental wave.

Depending on the specific situation, there are a variety of products that are used to mitigate harmonics. Fuseco's Power Quality Consultants can assist by conducting a site analysis or simply providing advice based on the details of the particular electrical system. Here is a brief summary of the product groups:

Line (input) side of the VSD

Device Features:

- Line Reactors Simple & cost-effective method to reduce harmonics. Available in 3% & 5% versions.

- Passive Harmonic Filters Significantly reduces harmonics from the VSD back out to the system and also improves true power factor.

- Meets the IEEE519 Standard.

- Active Harmonic Filters Active filters inject a 180 degree inverse current to nullify the harmonic content going back out to the system. They mitigate harmonics, compensate for voltage dips & can handle multiple VSD's relative to the reactive power required. Meets the IEEE519 Standard.

Load (output) side of the VSD

Device Features:

- Load Reactors Simple & cost-effective method to reduce harmonics. Available in 3% & 5% versions.

- dV/dT Filters dV/dT filters have been designed to limit peak voltage and increase voltage rise time. In addition to mitigating harmonics, the dV/dT filter also clips voltage spikes.

- Sinewave Filters The ultimate load side harmonic mitigation product. Filters all harmonics, including reflective currents, eddy currents, common mode currents. Can be used for long cable runs (many kms). Stops the heating of cables. Great for the longevity of motors.

Also known as Inductors, Chokes & Line Filters, Line Reactors are used on the input of a VSD, inverter or other non-linear devices. Line Reactors have the following features:

- Virtually eliminate nuisance tripping.

- Extend life of semiconductors.

- Reduce harmonic distortion.

- Reduce surge currents.

- Improve true power factor.

Manufacturers of variable speed drives (VSD) nowadays are operating in an extremely competitive marketplace, and there is a tendency to offer drive products without input reactors unless the end user specifically requests it. Users, though, often are not familiar with the reasons why a reactor is beneficial both for the reliability of the drive's electronics and for the quality of the power supply.

- A reactor buffers the electronics from input transients due to utility and load switching elsewhere in the supply.

- A reactor prevents high inrush currents and reduces the transient load on the input components.

- A reactor improves VSD/VFD crest factor, reducing power input line losses.

- A reactor controls emissions of line current harmonics due to the rectifier input circuit.

- A reactor controls the impact of commutation notches on the power supply.

- A reactor protects and increases the service life of DC link capacitors of VSD's.

- A reactor reduces differential-mode low-frequency phenomena up to a few hundred khz.

Reactors are exempt from requiring a "Short Circuit Current Rating" under the standards.

No, so long as you are consistent for all three phases.

Reactors are available from very low impedance values < 1% to high impedance values > 15%. Most commonly used reactors available are 3%.

A reactor of higher impedance equal to or greater than ≥ 4% will mitigate more harmonics but will also have greater energy losses.

A reactor of higher impedance equal to or less than ≤ 1.5% will have less energy losses but also mitigates slightly less harmonics.

As long as the incoming power is strong and does not already reflect depressions or downward swings in line voltage, adding a harmonic filter to a drive system that already has a built-in 2.5% line reactor will not be a problem. It is very important to have the series line reactor in the filter circuit. If the 2.5% added voltage drop at full load is a concern, it is recommended that the drive customer to remove the drives internal 2.5% line reactor. The series inductor designed into the harmonic filter provides an inductance value that is important to the level of harmonic mitigation performed by the filter.

Yes, an independent third party test was conducted to evaluate the use of harmonic filters on bypass systems. The concern is to ensure the series inductor does not provide too excessive of a line voltage drop to prevent proper operation of the bypass control contactors. A 75 HP NEMA design A motor and drive package with a bypass option was tested. Extensive testing showed that the voltage drop across the 480/120 volt control power transformer being caused by the series reactor was approximately 10% at full load which was well within the contactor coils dropout rating. The bypass circuit worked very well and the results concluded that a harmonic filter can be used with a standard drive/bypass configuration without any special system modifications.

They can be used in line with the power input (line reactor), in the DC link between the rectifier and capacitor (DC link choke) and at the drive output to the motor (motor reactor). A reactor at each of these positions has specific effects that are by no means mutually exclusive. The functions of the input line reactor are quite different from a filter at the drive output, and it is entirely reasonable to include both of these in a system.

Also known as 'Low Pass Filters', Passive Harmonic Filters reduce harmonics at the VSD, inverter or other non-linear devices. Passive Harmonic Filters have the following features:

- Reduce harmonics to 5-6%.

- Reduce cable heating and line losses.

- Improve power factor.

- Reduce system loss.

- Minimise interference with other equipment.

- Improve system voltage/current waveform.

- Prevent nuisance tripping of fuse and circuit breakers.

- Meet the IEEE519 Standard.

An Active Filter is a device used on the line (input) side of a VSD or a group of VSD's. Active Harmonic Filters are mainly used for group harmonic compensation at the main switchboard.

Active filters inject a 180 degree inverse current to nullify the harmonic content going back out to the system. Active Harmonic Filters have the following features:

- Reduce harmonics to 5% or less.

- Reactive current control.

- Compensate for voltage dips.

- Load side transient suppression.

- Load side surge suppression.

- Reduce of supply sags and surges.

- Can handle multiple VSD's relative to the reactive power required.

- Improve electrical system efficiency.

- Reduce operations and maintenance costs.

- Meet the IEEE519 Standard.

Also known as Motor Chokes, Load Filters & Inductors, Load Reactors are used on the output side of a VSD, inverter or other non-linear devices. Load Reactors have the following features:

- Reduce harmonics to 5% or less.

- Protect motors from long lead effects.

- Reduce reflective currents.

- Reduce Harmonic Distortion.

- Reduce Surge Currents.

- Reduce Motor Temperature.

- Reduce Motor Audible Noise.

dV/dT filters are designed to protect AC motors from the destructive effects of long lead peak voltages. dV/dT Filters have the following features:

- Increase bearing life and up-time.

- Reduce common mode noise and currents.

- Prevent voltage spikes from exceeding 1kV.

- Reduce motor peak voltages.

- Protection of motor insulation.

- Reduce motor operating temperature.

The main purpose of the filter is to address and control the effects of dv/dt on the VFD output. Because of the circuit used, the filter also reduces the content of common mode current on the line by 30-40%. This is especially useful in the prevention of motor shaft bearing currents which are known to cause premature motor bearing failures in adjustable frequency drive applications.

A very positive effect of a dV/dT output filter is to greatly reduce the amount of common mode current on the line. Common mode current is the phenomenon which causes motor shaft bearing currents and the resulting motor bearing failures. By reducing this current, motor bearings can enjoy a longer service life. A dV/dT filter will not eliminate this current but will reduce the line content between 30 and 40%. This is notable and very much needed in motor and drive applications.

A dV/dT filter is a drive output filter that addresses dV/dT. This filter is very affective in this cause and can protect standard and special service electric motors from the damaging affects of dv/dt. A dV/dT filter however, does not return the drive output square wave to a sinusoidal waveform and thus is not referred to as a Sinewave Filter.

A Sinewave Filter is designed specifically for those applications where extremely low distortion and near perfect sine wave performance is required.

Most dV/dT filters are designed and developed to cover the vast majority of NEMA frame motor applications through 600 HP at 480 volts. Above that current level a dV/dT filter can be paralleled to achieve the performance of using a single device. For example if 1,500 amps is required, two 750 amp units can be wired in parallel and connected through a common power block on both the line and load side of the filter.

A dV/dT output filter is designed to be located directly next to the VFD. It is recommended that the filter be located within 10 feet (3 meters) of the drive to properly handle the voltage distortion, dV/dT, before it escalates on the line and causes damage to the motor and lead cables.

A dV/dT filter consists of two major components. The first part of the filter is a series line reactor which dampens the voltage distortion on the output of the VFD. The second component is a snubber circuit which effectively reduces the voltage distortion, dV/dT, to 1,000 volts per micro second on a typical 480 volt system. These two components are very effective at protecting the electric motor and the affects of dV/dT on the output side of the drive.

The dV/dT output filter can be used on most commercial and industrial applications were the motor is located at an extended distance from the VFD. Typical applications include HVAC fans, pumps, conveyors, drilling applications, and other drive applications where the motor is located from approx 30m to 1000m from the drive.

The dV/dT output filter is designed to limit the peak voltage to approximately 1,000 volts. These filters are successful in most simple drive/motor applications where lead lengths are about 1000m or less, and a modulated output waveform is acceptable to the load. In terms of a line reactor, the inductive reactance achieved with a line reactor works to slow down the rise time of the spike but can do nothing to limit the magnitude of it. A Sinewave Filter goes beyond this to eliminate the carrier frequency effects in the modulation process. The result is a smooth sinusoidal waveform and load friendly power supply.

In addition to protecting the motor, the sine-wave filter also provides protection for the VSD/inverter. Sinewave Filters have the following features:

- Unshielded motor cables can be used resulting in lower project costs.

- Motor operating life is increased.Longer motor cables are possible.

- Significantly lower eddy current and stray flux losses.

- Significant reduction of bearing currents.

- Eliminate torque ripple.

- Eliminate voltage wave reflection.

- Reduces motor noise, vibration and heat.

A Sinewave Filter is a high performance L-C-R, low pass filter. This is a tuned filter which combines inductance, capacitance, and resistance.

The objective of the filter is to duplicate the efforts of typical power utilities. According to utility standards, the power quality is to limit voltage distortion to approximately 5%. This is well within the operating standards of any conventional squirrel cage induction motor. It is well accepted by any standard transformer as well should the load to the filter be a transformer.

Harmonic filters are used where drives are a significant portion of the load. Prime candidates for filtering are installations of variable frequency drives or adjustable speed devices in facilities where those drives represent a significant portion of the load, or when specifications call for limited harmonics as per the applicable standards.

The performance doesn't fall off with the load and superior performance is achieved at 100% and 50% load.

At present there is not a passive harmonic mitigation device as we know it, the HG7, for single phase drives. But one can use a three phase reactor in a single phase circuit that will perform limited mitigation.

High endurance capacitors are critical in the service life of any harmonic related device. The harmonic current that flows through any harmonic filter is extremely harsh and hard on electrical components. Early in the development life of the first harmonic filters it was found that a high endurance or harmonic rated capacitor were critical to ensure long service life. Standard power factor correction caps or motor starting caps are a poor way to protect the service of your filter and your drive system. While the high endurance capacitor is considerably more expensive, it has been found to be an important component that can be a great cost savings to the end customer down the road.

Harmonic filters are designed to work with any standard, 6 pulse, and PWM drive on a standard NEMA design motor. You should contact the supplier if the intention is to use the Harmonic filter on a drive system incorporating braking resistors or regenerative drive circuitry to ensure compatibility.

After studying the standard drive product offerings used in industry today. Standard, 6 pulse, PWM drives and standard NEMA design motors are compatible packages. These drives typically need no special adjustment when using a harmonic filter. If your drive application is utilizing unique drive components, contact your drive manufacturer's technical support staff for clarification on limitations to harmonic mitigation equipment.

The best way for true power system evaluation is to have an actual power measurement taken at the facility. For the sake of an informal, computer assisted power system review, TCI offers the Analyser Program found on the TCI website at www.transcoil.com. Contact TCI Technical Support for assistance on this and other thoughts on compliance with IEEE-519 standards.

A harmonic filter comes complete with a series line reactor as part of its design. A separate line reactor is not normally required.

As long as the incoming power is strong and does not already reflect depressions or downward swings in line voltage, adding a harmonic filter to a drive system that already has a built-in 2.5% line reactor will not be a problem. It is very important to have the series line reactor in the filter circuit. If the 2.5% added voltage drop at full load is a concern, it is recommended that the drive customer to remove the drives internal 2.5% line reactor. The series inductor designed into the harmonic filter provides an inductance value that is important to the level of harmonic mitigation performed by the filter.

Yes, an independent third party test was conducted to evaluate the use of harmonic filters on bypass systems. The concern is to ensure the series inductor does not provide too excessive of a line voltage drop to prevent proper operation of the bypass control contactors. A 75 HP NEMA design A motor and drive package with a bypass option was tested. Extensive testing showed that the voltage drop across the 480/120 volt control power transformer being caused by the series reactor was approximately 10% at full load which was well within the contactor coils dropout rating. The bypass circuit worked very well and the results concluded that a harmonic filter can be used with a standard drive/bypass configuration without any special system modifications.

Harmonic filters are designed to focus on drive-applied applications but can be sized for multiple motor systems as well. Caution must be taken to size the unit properly as well as to take all of the power system variables into consideration.

The best way to address specification and harmonic limits is to do a proper analysis of your power system to establish a base line value of the harmonics presently on the power system at the point of common coupling, (PCC). Once that value is found, a proper solution can be formulated for your facility. For specifications that state a specific value at the drive or filter terminals, typically provide a harmonic filter that will meet the limits of most power quality specifications. Most industry power quality people today rely on the committee studies and findings of IEEE/IEC. The guideline that IEEE/IEC established is their standard 519. Most drive-applied harmonic filters are capable of achieving the standard when the customer evaluates the harmonic content at the point of the drive or filter terminals. This standard has reached an industry wide level of acceptance, and most power quality Engineers will reference this standard and openly accept the performance of harmonic or low pass filters for drive applied applications. For additional information of IEEE/IEC -519 requirements please consult the standards references.

Power quality specifications can be difficult to interpret and often times confusing. For accurate definitions of the standards and a discussion involving easy to understand information, contact our technical support team.

You can use the HG7 on generator power; however it is more critical to size the device properly. If the nonlinear load represents a great portion of the total generator load and the drive is very lightly loaded, the filter capacitance may cause the generator to experience voltage regulation issues. You may also contact the generator provider for their guidelines on the use of harmonic mitigation and capacitive equipment on their systems.

These frequencies can be from either noise conducted through power lines or radiated through the air onto the power lines.

Common mode noise is the electrical noise on all power lines with respect to ground. Differential mode noise is the electrical noise on one line with respect to another line. When considering a filter for use in a variable speed drive application, it is important to note that common mode noise reduction is the most important factor. Variable frequency drives produce very little differential mode, or line to line, electrical noise due to the presence of DC bus capacitors.

Unlike input or line side devices where the drive input current becomes an important part of the selection and sizing criteria, output devices are sized based on the load itself. The load determines the current that will be drawn through the filter. Merely size the filter based on the full load amp, (FLA) rating of the motor. We suggest you size the filter no more than 110% of the drive output filter to ensure a proper match between drive, load, and filter.

Like virtually all passive devices, there is an associated loss factor. The actual equipment efficiency depends on the RMS current loading. The power resistors are voltage, not current sensitive, and will experience a constant loss factor. Full load loss information is generally stated in watts.

The IEEE is the Institute of Electrical and Electronics Engineers.

IEEE 519 is a document that was initially published in 1981 titled 'Recommended Practices and Requirements for Harmonic Control in Electric Power Systems'

The relevant standard for harmonic voltage distortion in Australia is AS/NZS 61000.3.6 and it is compatible with the IEEE 519 recommendations.

If the supply authority is unsatisfied with the degree of voltage distortion at the point of common coupling (pcc), harmonic filtering may be specified to comply with the Australian Standards.

Please refer to the table below for details about AS/NZS 61000.3.6

| Odd harmonics, non mulitples of 3 |

Odd harmonics, multiples of 3 (triplens) |

Even harmonics |

|||

|---|---|---|---|---|---|

| Order, h | % harmonic voltage | Order, h | % harmonic voltage |

Order, h | % harmonic voltage |

| 5 | 5 | 3 | 5 | 2 | 2 |

| 7 | 5 | 9 | 1.5 | 4 | 1 |

| 11 | 3.5 | 15 | 0.03 | 6 | 0.5 |

| 13 | 3 | 21 | 0.02 | 8 | 0.5 |

| 17 | 2 | >21 | 0.02 | 10 | 0.5 |

| 19 | 1.5 | 12 | 0.2 | ||

| 23 | 1.5 | >12 | 0.2 | ||

| 25 | 1.5 | ||||

| >25 | 0.2 + 1.1 (25/h) | ||||

NOTE: total harmonic distortion (TDHV) 8% max

related resources

Applicable Industries

Technical Support

Our experts are all pre-eminent leaders in electrical products who provide excellent support in their areas of expertise.

Technical supportTalk to an expert

Our friendly team are highly trained product experts who really enjoy helping customers find what they need.

call 1300 387 326Enquire by email

We promise to respond within 4 business hours (AEST) or you will receive $100 off your next purchase.

Enquire now